what mechanical properties does impact testing test|types of impact testing : chain store Mechanical Properties. The ductility and strength (measured by a tensile test), related hardness properties and fracture toughness (or impact resistance) are the three most frequently required materials properties. Studios Lionsgate Television + 3 more. Genres Comedy. Meet the team behind the biggest multiplayer video game of all time. But in a workplace focused on building worlds, .

{plog:ftitle_list}

webA diferença entre a Prestige 77BR e a Prestige 750 consiste na adaptação ao clima tropical. A plataforma de popa da Prestige 77BR é consideravelmente maior, com espaço .

Impact testing is a critical evaluation process that determines a material or product’s toughness, resilience, and durability when subjected to sudden forces or shocks. . An impact test is a technique used to determine a material’s ability to resist deformation when subjected to a sudden shock or impulse load. There are several different types of impact tests, but all entail striking a .The following sections contain information about mechanical tests in general as well as tension, hardness, torsion, and impact tests in particular.

Mechanical Properties. The ductility and strength (measured by a tensile test), related hardness properties and fracture toughness (or impact resistance) are the three most frequently required materials properties.

why impact testing is done

Various types of impact tests exist, with each test designed to measure specific material properties. The most commonly used test is the Charpy test, which involves striking a notched sample with a pendulum . Impact testing is a procedure that measures a material’s resistance to failure when subjected to high-rate loading. This method is used in multiple industries like automotive, aerospace, and construction to guarantee .Mechanical testing - notched bar or impact testing. Before looking at impact testing let us first define what is meant by 'toughness' since the impact test is only one method by which this material property is measured.Experiment: Mechanical Testing- Impact & Hardness Testing. Objective. The main objective of this experiment is to introduce two important basic mechanical property tests; hardness .

Impact testing is a critical method for evaluating the mechanical properties and fracture toughness of cast irons. The ASTM standard test methods provide standardized . 6 Types of Mechanical Tests. The most common types of mechanical tests include Tensile test, Compression test, Hardness test, Impact test, Fatigue test, and Torsion test. Tensile testing. Tensile testing is a type .

Before looking at impact testing let us first define what is meant by 'toughness' since the impact test is only one method by which this material property is measured. Toughness is, broadly, a measure of the amount of energy .of the ASTM Standards are relate directly to mechanical testing techniques including specifications for measuring the hardness and impact properties of materials. Background – Impact Testing Toughness is a measure of the amount of energy a material can absorb before fracturing. It becomes of

The test specimen in a drop-weight impact test is notched, and the weight is dropped on the surface opposite that of the notch. Like the other impact tests previously described, the drop-weight impact test is frequently used to test for a material’s ductile-to-brittle transition temperature. 4. Dynamic Tear Test Mechanical properties of the metals are associated with the ability of the material to resist mechanical forces and load. But basically, those properties are associated with stress and strain.

Material impact toughness can be measured by various types of test such as the Charpy V-notch impact test, Izod test or K IC test. The most commonly used test is the Charpy impact test (see Fig. 6.9), which gives an indication of the toughness of a material at a specified temperature.It is not a particularly accurate test but can give a general indication of the ability . What are mechanical properties? Mechanical properties of aluminium, like other structural materials, are properties that are associated with the elastic and inelastic response of the material to the application of a load to it. These properies include the relationship between stress and strain. Examples of mechanical properties are: Our discussion will cover the different types of impact testing, the necessary equipment, and the valuable data these tests provide. Impact Testing – Charpy and Izod Tests. The impact testing method is pivotal for determining a material’s ductile-to-brittle transition temperature and its ability to resist deformation due to impact loads.

Impact strength measures a material’s behavior under sudden loads, such as shocks or impacts. Measurement. Charpy or Izod impact tests are commonly used to assess impact strength. Units. Joules per square meter (J/m²) Foot-pounds per square inch (ft-lbf/in²) Example Materials High Impact Strength Material: Polycarbonate

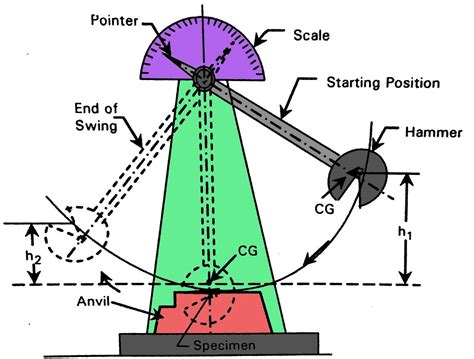

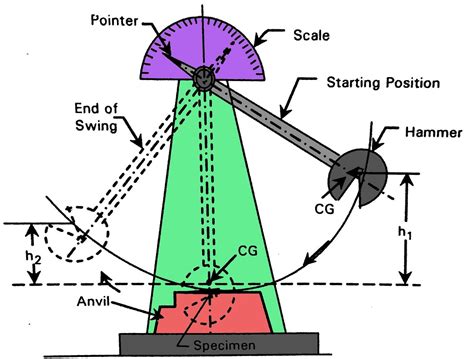

Charpy impact testing (also known as a Charpy V-Notch test) is a valuable method to determine the amount of energy a material absorbs during fracture. The test is performed when a pendulum head is dropped from a specified height and impacts a notched specimen of material.Purpose of the test. Impact testing is used to determine material behavior at higher deformation speeds. Classical pendulum impact testers determine the impact energy absorbed by a standardized specimen up to break by measuring the height of rise of the pendulum hammer after impact. What are the types of impact tests? Test Types. 2.1 Technique Schematic. Figure 1 presents a graphical depiction of the methodology for estimating the mechanical properties of rocks and rock masses based on mineral micromechanics testing. The scheme can be separated into two main steps: obtaining the micromechanical properties of constituent minerals through nanoindentation tests and .

In the equation for stress, P is the load and A 0 is the original cross-sectional area of the test specimen. In the equation for strain, L is the current length of the specimen and L 0 is the original length. Stress-Strain Curve. The values of stress and strain determined from the tensile test can be plotted as a stress-strain curve, as shown below:Tensile test. A standard specimen is subjected to a gradually increasing load (force) until failure occurs. The resultant load-displacement behaviour is used to determine a stress–strain curve, from which a number of mechanical properties can be measured.. There exists a large number of tests, many of which are standardized, to determine the various mechanical properties of .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material's notch toughness.It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and .ASTM's physical and mechanical testing standards provide guides for the proper procedures employed in the determination of the physical, mechanical, and metallographic properties of certain materials, particularly metals and alloys. . E2248-18 Standard Test Method for Impact Testing of Miniaturized Charpy V-notch Specimens .

Figure 2. Test Specimens Used For Material Impact Testing IMPACT TESTING AT ROOM AND ELEVATED TEMPERATURES Reference 1 discussed the procedure used to perform the impact tensile testing of base material at room, 300 oF, and 600 oF temperatures. The procedure for testing the welded material at these same temperatures was identical. Hence, the

An overview of mechanical and physical testing of composite materials. N. Saba, . M.T.H. Sultan, in Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites, 2019 1.2.3 Impact test. The impact test is designed to determine how a specimen of a known material such as polymers, ceramics, and composites will respond to a .

Tensile testing on a coir composite. Specimen size is not to standard (Instron). Tensile testing, also known as tension testing, [1] is a fundamental materials science and engineering test in which a sample is subjected to a controlled tension until failure. Properties that are directly measured via a tensile test are ultimate tensile strength, breaking strength, maximum . Specimen Shape and Gripping; Measurement of Load and Displacement; Displacement Measuring Devices; The uniaxial tensile test is the most commonly-used mechanical testing procedure. However, while it is simple in principle, there are several practical challenges, as well as a number of points to be noted when examining outcomes. Mechanical testing is a process used to evaluate the mechanical properties of materials, providing valuable insights into how they will perform under various conditions. These properties include strength, hardness, elasticity, toughness, and more. . Common types of impact testing include: Charpy Impact Test: Imagine swinging a small hammer at .

feuchtigkeitsmessgerät action

feuchtigkeitsmessgerät aldi nord

General Types of Mechanical Testing. The mechanical test process is very wide-ranging. There are several types of mechanical testing options available to a mechanical test engineer. In this section, we will discuss the most common tests that engineers use. Stress Testing. Stress testing is the most common mechanical test in manufacturing.Mechanical Properties and Testing of Metals. Ramesh Singh, in Applied Welding Engineering, 2012. Testing of Metals Tensile Test. Tensile testing is used to establish operational load limits for metals and alloys. A sample of the material is prepared so .

Tensile testing or Tensile Test is also known as Tension Test is a Destructive Test method and the most common type of mechanical test. . Therefore, it is a significant factor when designing parts for low temperature and toughness properties (Impact load). Similar Posts. What is Bend Test in welds, & Types of Bend Test;

The originally performed perforation experiments were extended by compression and tensile dynamic tests reported in this work in order to fully characterize the material tested. Metallurgy - Testing, Mechanical Properties: The most common mechanical properties are yield stress, elongation, hardness, and toughness. The first two are measured in a tensile test, where a sample is loaded until it begins to undergo plastic strain (i.e., strain that is not recovered when the sample is unloaded). This stress is called the yield stress. It is a property .

Intertek’s mechanical testing of metals uses impact, tensile and hardness testing to determine whether a metal is suitable for its intended use. . Intertek has a range of testing machines that can test up to 1000kN. Intertek also has the capability to test at elevated temperatures and NDT Services Ltd, which is a subsidiary of Intertek, has .

what is impact testing

types of impact testing

WEB5 de jul. de 2023 · O que são recursos naturais? A princípio, os recursos naturais são classificados como todos os elementos que estão disponíveis na natureza, sem a ação .

what mechanical properties does impact testing test|types of impact testing